It’s perfect

A perfect surface finish has been the dream of manufacturers and brand owners for decades. Now, that dream has become a reality.

In partnership with KU Leuven University Gent, Rhopoint Instruments has designed a new system for quantifying surface appearance.

Why use Aesthetix?

Match what the eye sees

Create the perfect surface finish by measuring all the parameters that affect visual appearance and match what your eye sees.

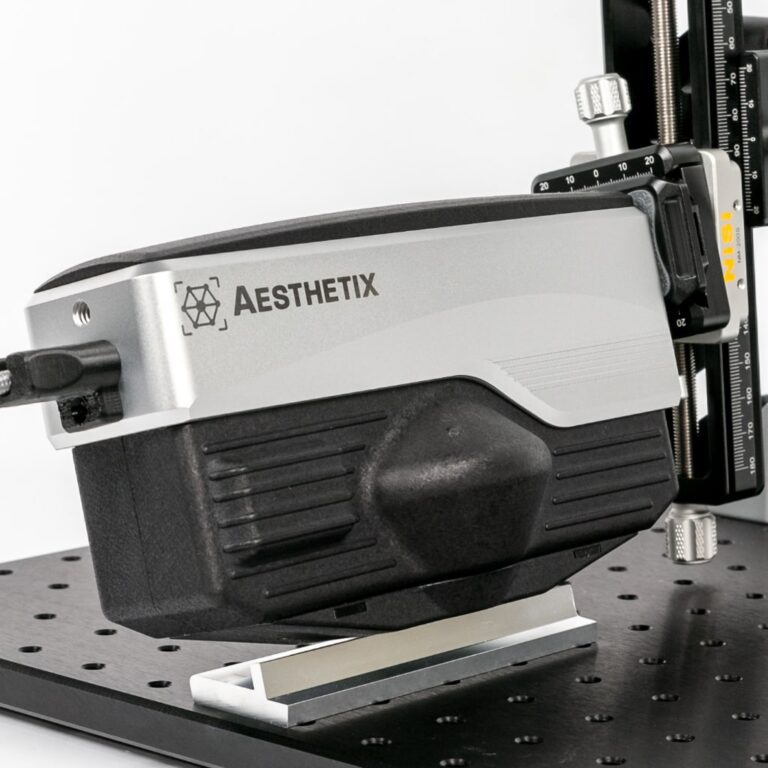

Aesthetix Vision Sensor

A dual camera sensor with innovative lighting captures HDR surface and gloss images with exceptional resolution lower than the human eye.

Aesthetix Vision Engine

The Rhopoint Appearance Element software uses perception algorithms to calculate parameters that predict the human visual response to important surface characteristics.

Compares standards against visual judgement

Uniquely, the Rhopoint Appearance Element software allows technical control based on ISO or ASTM standard procedures and at the same time, checks for visual judgment.

How does Aesthetix characterise visual perception of surfaces?

For many decades, the visual perception of surfaces has been an important research topic for many academic institutions and dates as far as the work made by Pfund and Hunter in the 1930s.

Newest studies found that the human vision system subconsciously considers multiple visual cues when judging or comparing surfaces.

The Aesthetix adopts a similar approach – capturing multiple surface images which represent the optical characteristics of the surface modified for different viewing conditions.

Aesthetix® Modular System

Surface Brilliance

A combination of perception metrics that comprehensively describe the reflectivity and visual quality of high-quality, high-gloss surfaces.

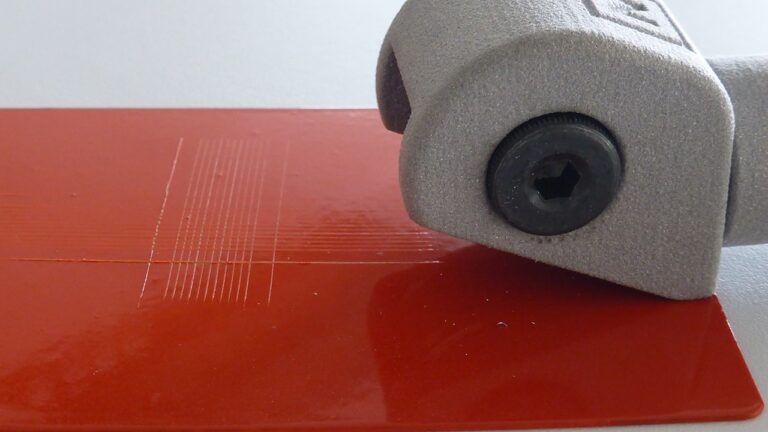

Cross-cut Adhesion

Aesthetix Cross-cut Adhesion Module replaces the subjective analysis of reproducible imaging measurement, increasing the speed and accuracy of a critical test which quantities durability and performance of a coating under various conditions.

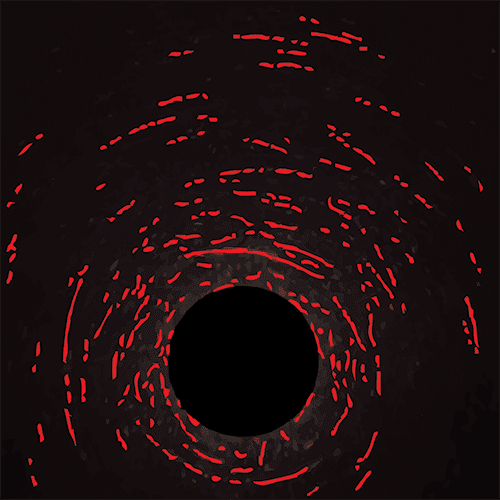

Effect Finish

Coatings with effect pigments exhibit sparkle and coarseness. Sparkle refers to a visual texture observed when mirror-like elements within a surface reflects light.

Polishing Quality

The Rhopoint Polishing Quality Module is designed to objectively quantify scratches, holograms, and swirls on high-gloss automotive surfaces. Additionally quantifying gloss, haze, sharpness / DOI for a complete surface characterisation. Ideally suited for manufacturers optimising polishing processes and evaluating spot repairs.

Texture

Materials with surface texture such as automotive interior plastics, leather and powder coatings need to have uniformity of appearance and pattern to have maximum visual appeal. The Rhopoint Aesthetix® analyses surface texture to help manufacturers create consistent products with optimum visual appearance and tactile qualities.